Month: September 2021

When commercial business owners and facility engineers consider the many building issues that may lead to sick occupants, it’s likely mold and other indoor allergens

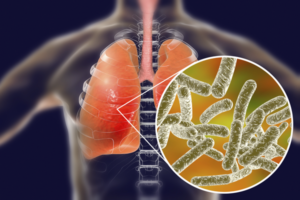

First identified in 1977, Legionnaires is a form of pneumonia made up of bacteria called Legionella. The disease’s name comes from its origin at an American Legion convention, which resulted in 180 attendees falling ill and 29 deaths.

Formed when bacteria enter the lungs either by breathing in very small droplets of water or when water accidentally gets into the lungs while drinking, Legionnaire’s Disease produces flu-like symptoms. Headaches, muscle pain, chills, fever, and fatigue can occur between two to ten days from exposure to Legionella bacteria—especially in immunocompromised populations. Although most healthy people do not get sick when exposed to Legionella bacteria, the best cure is prevention, as complications of the disease can lead to lung failure.

Locating Legionella

Legionella tends to thrive in areas such as hot water tanks, cooling towers, plumbing systems, and even condensation from air conditioning units in addition to the obvious settings of fountains, pools, and hot tubs. Since water is where these bacteria live and thrive, water is where it will appear in commercial buildings.

Certain changes like building construction, water temperature fluctuation, water pressure changes, and antiquated equipment can all make Legionella more of a risk.

Hot water systems that store water and supply a commercial building’s functions can serve as a potential Legionella bacteria breeding ground. If the water in the water heater is maintained at a temperature of below 140° F and the water heater contains scale and sediment, this is a potential problem.

Likewise, cold water systems such as ice machines, grocery store produce misters, and dental water lines can be at risk for disease exposure. Even though these systems store water below 68° F, a temperature in which Legionella does not thrive, the environment around the water system could contribute to bacteria growth. For example, if an ice machine’s water lines are exposed to heat, say, from a condenser coil, this can foster bacteria growth.

Meanwhile, a commercial HVAC system may be a potential contamination source all throughout the building. Pipes leaking into air ducts can be a source of bacteria contamination, whereby the bacteria can spread through the air handling system.

In fact, any systems that use humidifiers and evaporative air coolers also have a potential risk factor if not well-maintained. Namely, coil and heat exchanger leaks and stagnant sump water are something to look at when mitigating Legionnaires’ Disease exposure.

Proper Prevention

Starting in the preconstruction phase, the thought given to the design of the plumbing, water, and air conditioning systems in commercial buildings is crucial. Legionnaires is much less of a risk if your facility’s design-build team efficiently conceptualizes and constructs a hygienic system.

Beyond design and construction, preventative maintenance is one of the best ways to keep Legionnaires at bay, as neglecting your water sourcing and plumbing systems can lead to a facility-wide outbreak. To ensure water source cleanliness and prevent stagnation, start with a water management plan that meets ANSI/ASHRAE Standards.

Binsky’s commercial team and plumbing experts always keep in mind that the design can help prevent the growth of bacteria and ensure easy maintenance and water management.

For hot and cold water systems, recirculating water and getting rid of tanks or capped plumbing pipes that allow water stagnation goes a long way, as does insulating lines to avoid temperature changes from other water lines or equipment.

Since the major source for Legionnaires in HVAC systems is water leakage, we check and properly maintain equipment, such as pipes, coils, and heat exchangers to ensure bacteria cannot grow. Checking and properly maintaining humidifiers, as well as cleaning evaporative air coolers before use helps. It is also key to ensure sump water remains at a cool temperature and never becomes stagnant.

As the maintenance plan is carried out, have your water tested for bacteria. If bacteria is in fact found, water can be treated and disinfected with copper-silver ionization or mono-chloramine to kill it off.

By installing advanced hygienic systems, executing timely preventative maintenance activities, you can avoid Legionnaire’s Disease in your commercial facility. Binsky can offer turnkey solutions to avoid Legionella. Stay up to date with your industry’s best standards and guidelines by partnering with Binsky for your facility needs.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.

Circulating the minimum amount of refrigerant in each individual zone, this innovative technology eliminates energy waste while increasing indoor comfort. A VRF system consists of one outdoor unit that feeds multiple indoor units, allowing for individual room controls. These systems operate in “cruise control”, never turning off, thus, never wasting energy from a shutdown or start-up. Predominantly used in Japan, China, and Europe, VRF systems are now gaining traction in the United States due to their efficient operation and quick ROI.

It is important to use an experienced contractor when designing and installing VRF systems for your facility. Install technicians can obtain factory training and certification from manufacturers including Mitsubishi, LG, Daiikin, and Fujitsu. When installed by certified technicians, a ten-year warranty is available on the parts and equipment. These technicians work very closely with the manufacturer during the install, commissioning the equipment, and guaranteeing the most efficient design.

Aside from cost and energy savings, another benefit of VRF systems is the ability to use zoom lock fitting technology. This is a pipe fitting method that does not require brazing or torching. Traditional methods of pipefitting require a burn permit while deactivating smoke detectors in the facility. The zoom lock technology in VRF systems eliminates these tedious steps in the early installation process. Depending on the system requirements, the zoom lock technology may offer you additional cost savings.

If you are considering a VRF system for your commercial or industrial space, contact Binsky to discuss your options. One of our certified technicians will perform a walk-through of your building and make recommendations that best suit your needs.

Subscribe to stay updated

Get the latest updates in the world of mechanical contracting and construction. Subscribe today!

Ready to Start Your Project?

Turn to a trusted leader in mechanical construction. Get in touch to discuss your project or request a quote today.